阅读时间 8分钟。

Borer Chemie, 28. 七月 2023

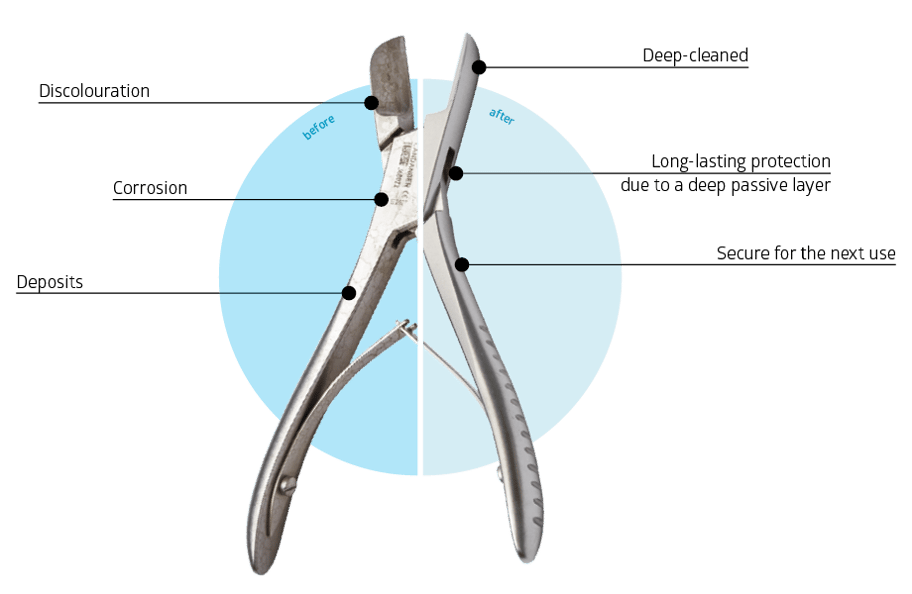

Is it possible to remove discolouration and stains from stainless steel surgical instruments and then passivate them with the same product? With deconex® 34 GR, the answer is yes!

A daily challenge: removing inorganic residue

Although they do not usually represent a risk from a hygiene perspective, inorganic residue can cause problems for the instruments' functionality. If it is detected too late, in the worst-case scenario an operation can be abandoned or delayed due to non-functioning instruments - and this is associated with enormous costs for the health facility!

So why take that risk if thorough cleaning, protection and value retention can all be achieved with deconex® 34 GR?

deconex® 34 GR: the multi-purpose formulation

Thanks to its formulation, deconex® 34 GR can be used for thorough cleaning and passivation using both manual and automated methods. This powerful product is also easy to use: surgical instruments are made like new in just two steps.

The first step: acidic thorough cleaning

The special formulation, involving a combination of phosphoric and nitric acid, can be used for both manual (including in an ultrasound bath, for example) or mechanical cleaning in the WD. With both options, a suitable process removes inorganic deposits and stains, the instrument shines like new again and its functionality is restored.

The added value: value retention thanks to subsequent passivation

The acidic thorough cleaning removes the passivation layer that has already built up, revealing the new instruments "original state". In a second step, the task is to build up a new passivation layer to ensure that the instrument retains its value.

Regenerating the passivation layer generally involves various methods and numerous steps and takes a long time. With deconex® 34 GR, passivation can be achieved with just one end-to-end automated process and the results are of the highest quality.

A study recently carried out by Borer Chemie AG in conjunction with the Empa (Eidgenössische Materialprüfungs- und Forschungsanstalt) impressively demonstrates that, while the usual citric acid-based passivation methods form a passivation layer of around 2 nm, a passivation layer five times thicker (10 nm) was formed with deconex® 34 GR.

Summary: one product, two applications, many advantages

The 2-stage process with deconex® 34 GR therefore not only removes inorganic residue from your stainless steel instruments, but also - thanks to the subsequent passivation step - also ensures that they retain their value.